Measurement of Coarse Wire in Steel Rolling Mills Using 2D/3D Profile Sensors

During the production of coarse wire in steelworks, billets up to 1,200°C must be rolled and then checked for geometric quality characteristics such as diameter, ovality, rolling or surface defects. There are specially developed measuring systems for this purpose that enable a 360° image of the wire in micrometer-precise resolution with four 2D/3D profile sensors each. In the profile sensors, which work ideally on red-hot steel with blue light, point clouds are initially created, which are then combined and visualized to form an overall image using 3D software.

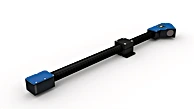

MLWL 2D/3D Profile Sensors

2D/3D profile sensors from the weCat3D series use the principle of laser triangulation to create 2D height profiles and 3D point clouds. The MLWL model offers unbeatable profile quality thanks to its optimized, high-quality optics.

Matching Products

The products listed here are ideal for use in this application.

Added to Your Cart:

Product Highlights

This area provides a deeper insight into this product world. All information about new product series as well as tutorials, templates and much more are combined here and are clearly prepared – tangible, understandable and traceable. Everything at a glance.